OVERVIEW

Over the summers of 2023 and 2024, I completed internships at Kiewit Corporation, one of North America's largest construction and engineering organizations.

As a Mechanical Engineer Intern, I worked on a variety of projects including preparing technical calculations and specifications, managing team meetings, and reviewing vendor drawings to gain firsthand industry experience.

Throughout this experience, some key skills I have demonstrated include:

•Critical analysis identifying flaws and solutions

•Coordination for the alignment of objectives across departments

•Adaptability in a fast-paced professional environment

Outside of technical work, I had fun participating in numerous social events, getting to know all of my coworkers and fellow interns!

WARRANTY TEAM AND JACKSON GENERATION

As a part of the Warranty Team in the summer of 2023, I was involved in different 9 power generation stations across the United States.

From pipe rerouting to bursted flange welds, each claim was unique, demanding new skill sets and experiences. These projects introduced me to a wide range of disciplines and allowed me to apply my knowledge to the power industry while collaborating with coworkers and fellow interns.

Additionally, I served as the point of contact to organize meetings with 7 project directors, coordinating to allocate tasks, transmit status updates, ensuring each claim was properly addressed. By engaging in these meetings, I had direct exposure to the management decision-making process. I was also able to see the immediate result of my team’s contributions through my direct correspondence with clients.

One claim I was heavily involved in was for Jackson Generation, a combined-cycle plant. When the field team did not install a pressure regulating valve on a skid inlet, the downstream equipment received150psig instead of 60psig.

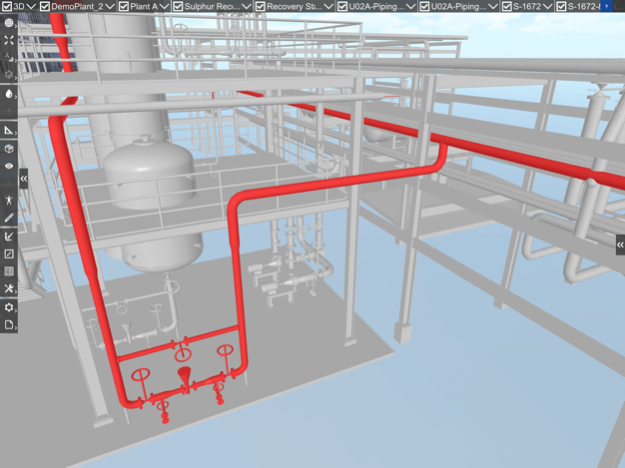

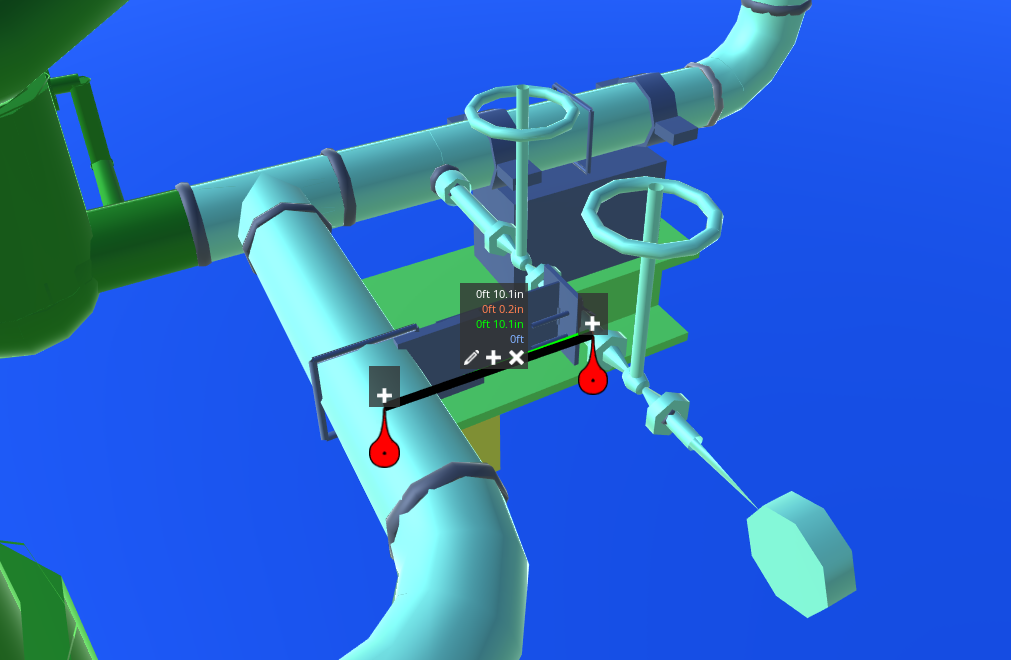

To address this, I first met with the project team and decided to install the regulator upstream. I then pulled the 3D model and determined where the regulator should be placed. Next, I rerouted the piping by accessing according P&IDs and redlined them to correct the issue.

The pressure gauges were now regulated as per spec, addressing client's concerns and also presenting opportunity for me to not only get in-depth on specific claim but also work closely with senior engineers.

TVA CUMBERLAND

As part of the TVA Cumberland Combined Cycle Plant team in the summer of 2024, I worked extensively with isometrics, 3D models, and vendor drawings.

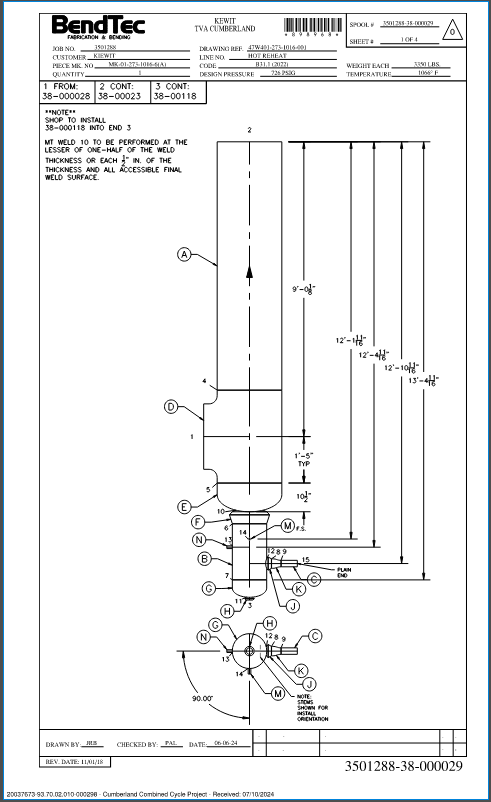

Working with the lead pipe stress engineer, I compiled the piping support details list for the high energy systems: high-pressure steam (HPS), hot reheat steam (HRH), cold reheat steam (CRH), and boiler feedwater (BFW). By comparing the 3D model to the isometrics, I ensured all equipment aligned correctly with the design specifications.

Additionally, after delivering the details list, I continued to see the project through by reviewing the corresponding vendor drawings, inspecting pipe material, sizing, and thickness. This experience provided me with an opportunity to build on my skills developed with the Warranty Team during the previous summer, working on a project with a wider timeline and scope than I was used to.

CONCLUSION

My internship at Kiewit has taught me how to adapt. Whether I was analyzing steam turbine schematics or verifying the details of an EPC contract, I quickly learned that in the engineering world, being flexible to meet constantly changing needs is vital. Kiewit has pushed me to be more detail-oriented and open-minded. Going forwards, I hope to continue to improve upon these skills and apply them to each facet of my career. Thank you Kiewit!